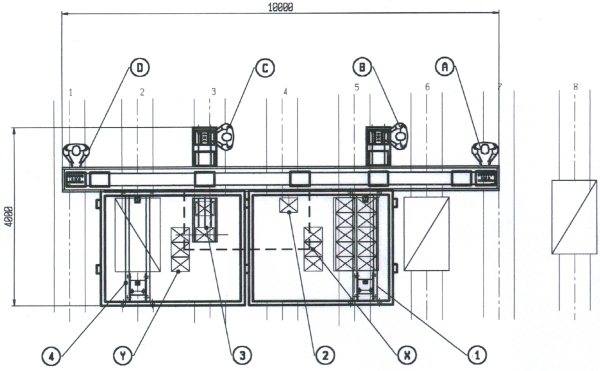

- automatýc grip to unload the anchors fuil ot biscuit cups from the car near the pile decompositor (2); storage in the parking (x) of at least 3 piles of anchors to have a stock for the non-stop during the car changing operation;

- pile decomposing component made up of a mechanical elevator and auto-centring grip for the transfer of the single anchors to the glazing machine feeding stations (A, B, C, and D);

- piles maker made up of auto-centring grip to hold the single anchors by the descending component; when the pile is complete the automatic grip loads the cars (4) and transfers the pile from the descending component to the already positioned car until the car self is full; in the meanwhile there is the storage of at least 3 piles of anchors in the parking (Y) to have a stock for the non-stop during the car changing operation. Then, after the empty car has come back in position, the automatic grip will collect the refractory anchors piles from the descending component in order to deposit them on the car, alternating it while recovering the piles deposited before in the parking, to transfer them definitively on the car.

A, B, C and D are cups unloading stations each of which is made up of 1 anchors deviation table to the unloading station with waiting station and uloading station on the descending component to eject the empty anchors on the empty anchors reversal lower line.

Production: no. 1 anchors every 7 seconds.

PRODUCTS

-

Pigment saggar unloading asystem and empty saggars palletization

-

Installation to load/unload kiln cars full of piles of anchors

-

Cups base finishing and polishing machine with collecting cups sucker device

-

Cups extraction and storage in a vertical storehouse installation

-

Kiln cars unloading/loading installation with refractory anchors containing biscuit cups

-

Automatic saggar loading and unloading unit for use with tableware